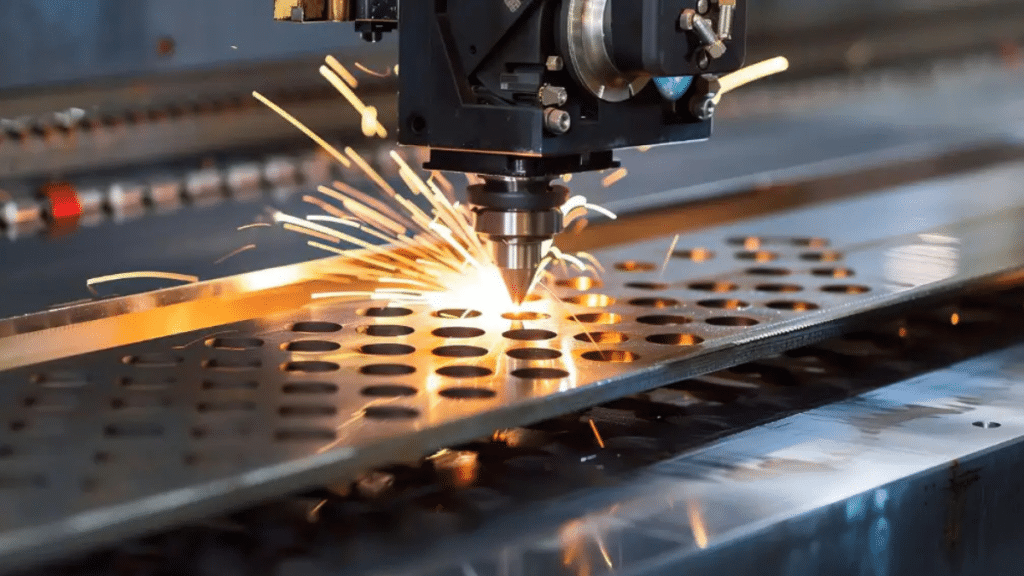

Laser cutting has become an essential service in industries ranging from automotive and aerospace to interior design and signage. Its precision, speed, and versatility make it ideal for cutting complex patterns into a variety of materials.

However, the cost of professional laser cutting services can vary depending on several factors. Understanding what influences pricing can help businesses and individuals make informed decisions when outsourcing this service.

1. Type and Thickness of Material

One of the primary factors affecting the cost of laser cutting services in Tennessee is the type of material being cut. Common materials include metals (such as stainless steel, aluminium, and mild steel), plastics, wood, and acrylic.

Harder materials like stainless steel require more energy and time to cut, which increases operational costs. Similarly, thicker materials take longer to cut through and may require more powerful equipment, which also drives up the price.

2. Complexity of the Design

laser cutting services in Tennessee are valued for its ability to produce intricate designs with exceptional accuracy. However, the more complex and detailed the design, the longer it takes to complete.

Designs with multiple curves, tiny holes, or fine details may require slower cutting speeds and multiple passes, increasing machine time and cost. Plus, if a design includes many components or varied shapes, it may also require more time for setup and programming.

3. Quantity and Volume

Production volume plays a significant role in pricing. Generally, larger quantities result in lower per-unit costs due to economies of scale. Once the design is programmed into the system, cutting multiple units becomes more efficient and less costly per piece.

But one-off or small-batch orders often carry a higher price tag because the setup time is the same regardless of volume, and the cost must be distributed over fewer items.

4. Machine Time and Labor

Laser cutting machines vary in their capabilities and efficiency. More advanced machines with higher speeds and better precision may command higher rates but can also finish jobs faster. The amount of labor required to set up, monitor, and finish a project (such as cleaning or deburring edges) also adds to the cost.

If specialised technicians are needed, or if the project involves post-processing like engraving or painting, those services are charged separately.

5. File Preparation and Design Work

Clients who provide ready-to-cut vector files (such as DXF or SVG) save time and money. If the service provider needs to convert images or drawings into a laser-compatible format, additional design and file preparation fees apply. Some providers offer in-house design services, which can be convenient but adds to the overall project cost.

6. Lead Time and Urgency

Rush jobs or tight deadlines can incur expedited service fees. If a project requires overtime hours or disrupts the normal production schedule, providers may charge a premium to prioritise the order.

Conclusion

The pricing of professional laser cutting services depends on a range of variables. For the most accurate estimate, it’s best to consult with a service provider and provide detailed specifications. Understanding these cost drivers empowers clients to optimise their designs and plan budgets more effectively.